- SOLIDWORKS PCB enables the productivity you need to design Printed Circuit Boards (PCBs) quickly along with unique, collaboration between electrical and 3D mechanical design teams. It offers a clear.

- Describes how to convert a simple PCB consisting of two conductor layers (Gerber) and a drill file (for vias) into a 3D Model in Solidworks. This approach uses Netex-G to create a 3Di file.

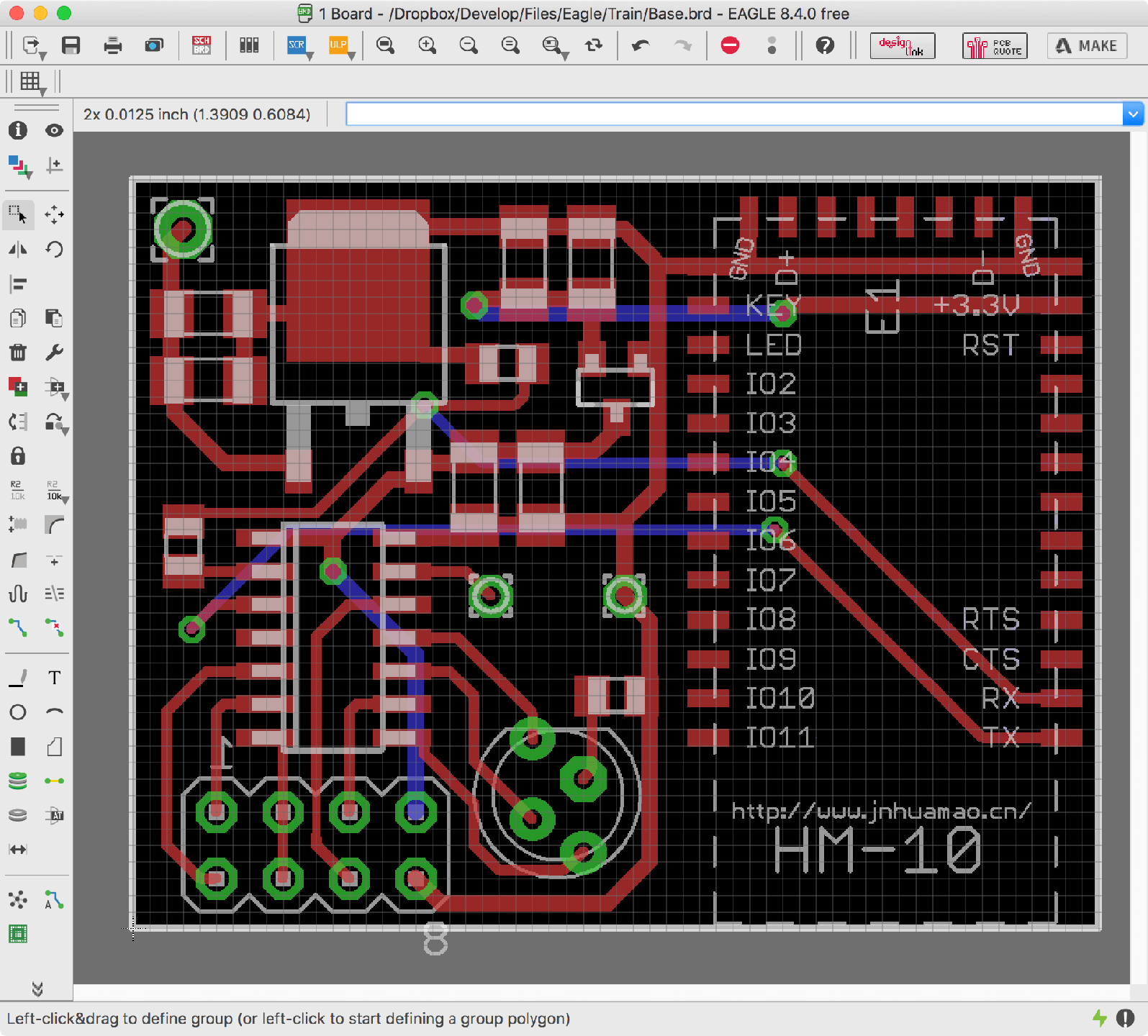

In this Gerber tutorial, I will teach you how to create the files you need for a 2-layer board using Cadsoft Eagle. After you have completed this tutorial you will have all the necessary files needed to send to most PCB manufacturers.

SOLIDWORKS PCB proudly supports most Altium documents. All documents contain the same file extension, while the PCB document requires a very short import pro. SOLIDWORKS designers who need to make masks for PCB or for integrated circuits can use STL2GBR which translates STL files to Gerber and STL2GDS which translates STL to GDSII. Artwork also supplies a tool to import Gerber, ODB, or GDSII.

This tutorial is out of date. I have switched to KiCad, so I recommend the updated tutorial How to Create Gerber Files in KiCad.

Step 1: Open the CAM Processor

In Eagle, open Board view. Click the “CAM” button or choose “File->CAM Processor”. This will open the CAM Processor tool that is used to generate the files.

Here you can define the sections you want to create files for.

But you don’t really need to understand this. Actually I have never really thought about the details of this until I was writing this article. I have just been using ready-made configurations. And that is probably what you want to do as well.

Step 2: Open a predefined job

To simplify creating Gerber files, Eagle comes with a predefined job for this. It is called gerb274x.cam.

(Note: If you want to order PCBs from Seeed Studio’s Fusion PCB service, you should instead download their own CAM-file from the bottom of their submission guidelines page. Be aware that this will give you different file names than the ones listed below in this article.)

To open it in the CAM Processor click “File->Open->Job…”

Browse to your …/eagle/cam/ folder, and you should see a file called gerb274x.cam. Choose it and click “Open”.

You will now see five tabs in the CAM Processor. Each of these tabs will generate a Gerber file.

Step 3: Adding a second silk screen (Optional)

If you look at the tabs, you will see that you don’t have a file for silk screen bottom. For simple boards, the silk screen is usually on the top layer so that you don’t need the bottom. Some of the cheap circuit board manufacturers don’t even allow bottom silk screen.

But if you need silk screen on bottom layer as well, follow these steps:

- Click “Add”

- Change Section to something like “Silk Screen SOL”

- Change File to “%N.pls”

- Deselect all layers

- Select layers 20 “Dimension”, 22 “bPlace” and 26 “bNames”

There you go.

Step 4: Create each gerber file

Select where you want to put the Gerber files by clicking on the “File” button and choosing a folder. Do this for all the tabs.

Then click “Process Job”. This creates your Gerber files.

Step 5: Adding file for drill holes

Even though drilling is supported by the Gerber format, manufacturers usually want the Excellon file format for specifying drill holes. Luckily, Eagle also comes with a predefined job for creating a drill file.

(Note: This step is automatically done if you’re using the CAM-file from Seeed Studio that I linked to in step 2.)

Solidworks Pcb Tutorial

Open it in the CAM Processor by clicking “File->Open->Job…”

Browse to your …/eagle/cam/ folder, and open the file named “excellon.cam”.

Select where to put the output file by clicking on the “File” button.

Solidworks Pcb Open Gerber Files Pdf

Then click “Process Job” to create your Excellon file.

Step 6: Check output files

You should now have the following files:

- *.cmp (Copper, component side)

- *.drd (Drill file)

- *.dri (Drill Station Info File) – Usually not needed

- *.gpi (Photoplotter Info File) – Usually not needed

- *.plc (Silk screen, component side)

- *.pls (Silk screen, solder side)

- *.sol (Copper, solder side)

- *.stc (Solder stop mask, component side)

- *.sts (Solder stop mask, solder side)

After you have created each gerber file, you should always look at them using a Gerber viewer to make sure everything is ok.

Summary

Solidworks Pcb Tutorial Pdf

This Gerber tutorial shows one way of creating the files you need. Even though this should be OK for many PCB manufacturers, you might find that some would want the files created in a slightly different way. If so, don’t worry, they will probably provide you with a Job file you can load directly into Eagle or at least have a good explanation on how to do it on their website.

Solidworks Pcb Open Gerber Files Extension

Check out more articles on PCB design by clicking this link:

Return from Gerber File to PCB Design